CAPITAL PROJECTS

Zero-Based Analysis

Understanding there is always more opportunity

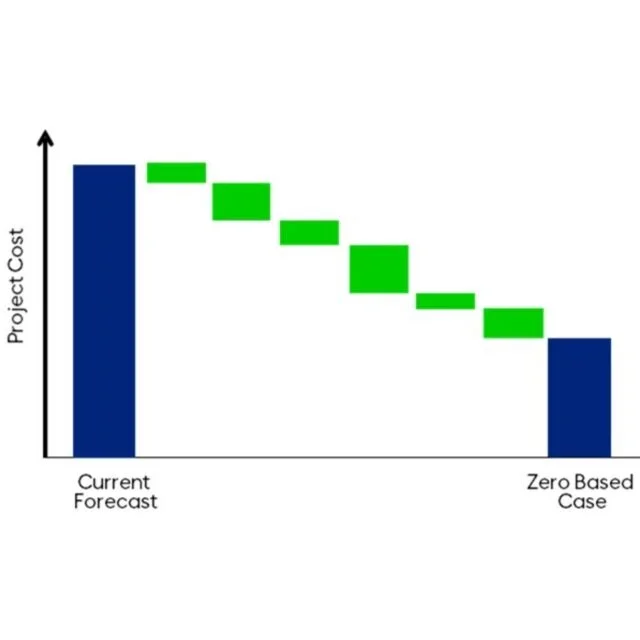

Zero-Based Analysis (ZBA) is Stroud’s unique approach to uncover all the potential opportunity within a project. ZBA starts by together answering the question: “What would the project look like in a perfect world?” through comprehensive analysis and challenging all constraints and assumptions. It then compares this “perfect world” scenario to the current plan to quantify all theoretical sources of opportunity.

The main principle of ZBA is to identify the “theoretical best” project that:

Meets all operational and safety requirements

Has the minimum required scope at the lowest possible cost

Has the shortest and most effective execution schedule

Provides the highest possible operating return

Teams then prioritize these opportunities by value and complexity to find the “biggest bang for their buck” that can most often be achieved within weeks. Together teams evaluate each top opportunity, get the facts, and drive to firm decisions that eliminate churn.

1. Identify All Opportunity

2. Prioritize Opportunities

ZBA process (typically 2 weeks)

Align on the project objective and primary value metric (e.g. capital cost reduction, increase in IRR).

Break down the project into subsets by scope or discipline, and analyze each in a dedicated working session.

Ensure participation from the right stakeholders in each ZBA working session. Together the team will identify value drivers and the “theoretical best” state for each through two questions:

What drives the value of this aspect (scope or process)?

What is the “perfect world” state of each value driver?

For each value driver, compare the theoretical best to the current state - any difference represents a theoretical opportunity!

Prioritize these opportunities by value and complexity (“bake the realism back in”), and align on the top ones to pursue.

Pipe cost example

1. Identify value drivers

Using the Variable Analysis method, your team to breaks down each aspect of a project into its value drivers.

E.g. Value drivers for Pipe Cost are Length & Cost Per Unit Length

2. Understand the “theoretically best”

Expand the value drivers until reaching a direct design decision or assumption, and ask “What would this be in a perfect world?”

Comparing that to the current state enables your team to determine all potential the opportunities in a project.

Prioritize opportunities by value and complexity and align on the top ones to pursue, ensuring your team is always going after the highest-impact items.

For example, the economically “perfect” routing would be a straight line between the start & end points.